|

The Incredible AXIS Lock

So, you might ask, what's the big deal about this AXIS Lock and why should you care? Allow me to explain. So, you might ask, what's the big deal about this AXIS Lock and why should you care? Allow me to explain.

Anyone who has spent any time at all perusing the Equipped To Survive™ site knows that I believe that a non-locking folding knife is so damn dangerous that they would be outlawed, if they weren't so entrenched. That isn't to say that the commonly available blade locking mechanisms aren't without fault. They all have their drawbacks, some more serious than others.

The most inexpensive and simple common blade locks are the lockback and the liner lock, once rare, now becoming common on even less expensive knives. Both come in many variations, some better than others. Readers are likely quite familiar with both styles. The quality of these locks runs the gamut, from poor to excellent, but the majority all exhibit some common shortcomings, to one degree or another. In no particular order they can include strength, actually lack thereof, reliability problems, possibility of inadvertent release, and potentially injurious action in use. Many blade lock designs have been developed over the years in an attempt to address some or all of these potential shortcomings. Some even work pretty well, to one degree or another. One design just works--period.

Back in 1998 a new blade lock design was introduced that addressed all these concerns, developed and patented by custom knifemakers Bill McHenry and Jason Williams. McHenery and Williams spent four years developing the lock and getting

it patented. Benchmade Knife Comapany bought the rights and tagged the new lock with the moniker "AXIS Lock." The first production knife to incorporate the AXIS Lock was the Model 710 and it, and the lock, were an immediate success that sent everyone looking for ways to achieve similar results without infringing on the patent. Nothing, to date, comes close to being as elegantly simple and effective. Back in 1998 a new blade lock design was introduced that addressed all these concerns, developed and patented by custom knifemakers Bill McHenry and Jason Williams. McHenery and Williams spent four years developing the lock and getting

it patented. Benchmade Knife Comapany bought the rights and tagged the new lock with the moniker "AXIS Lock." The first production knife to incorporate the AXIS Lock was the Model 710 and it, and the lock, were an immediate success that sent everyone looking for ways to achieve similar results without infringing on the patent. Nothing, to date, comes close to being as elegantly simple and effective.

Awestruck

| RSK Mk1 AXIS Lock cut-away animation

May take a few seconds to load (336 Kb)

|

The first time I saw the AXIS Lock in action I was awestruck. It's a real, honest to God, forehead slapping experience--it is so simple your immediate reaction is, "Geeze, why didn't I think of that?" Most of those whom I have handed one of these knives to the first time say exactly those words! Its advantages are so innately obvious, all you can do is shake your head in wonder.

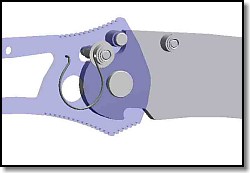

So, what is the cause of all this commotion? Boiled down to its basics, the lock is comprised of a spring-loaded bar which rides in a fore and aft slot cut out of both liners/side plates, traversing completely across the slot the blade folds in to and out of. It engages a ramped notch cut into the tang portion of the knife blade when it is opened. The knife tang is thus wedged solidly

between a stop bar and this AXIS Lock bar.

Suffice to say, it's a lot easier to show than describe, as you can see in these cutaway drawings. The animated GIFs clearly show how the AXIS Lock bar moves to engage the ramp on the tang of the blade.

Advantages

Let's review some of the advantages the AXIS Lock delivers, in

no particular order. Operationally, the lock can be, and is in all the knives produced so far, completely ambidextrous since the locking bar extends through both side plates. While the lockback is also ambidextrous, the liner lock is not, and with few exceptions, southpaws have been left out in the cold when it comes to liner lock knives. If you have an injured hand or are limited to using the "wrong" free hand because the other is engaged saving yourself, this can be a real, and potentially life-threatening handicap when you need to put away a knife or risk losing it. Let's review some of the advantages the AXIS Lock delivers, in

no particular order. Operationally, the lock can be, and is in all the knives produced so far, completely ambidextrous since the locking bar extends through both side plates. While the lockback is also ambidextrous, the liner lock is not, and with few exceptions, southpaws have been left out in the cold when it comes to liner lock knives. If you have an injured hand or are limited to using the "wrong" free hand because the other is engaged saving yourself, this can be a real, and potentially life-threatening handicap when you need to put away a knife or risk losing it.

The lock is naturally and easily operated, it is obvious even to those not mechanically inclined. Many people, faced with either a lockback or liner lock for the first time, simply don't get it, as hard as that may be to believe for many of us who are into these tools or more mechanically inclined. Every person I showed have shown a knife with the AXIS Lock immediately figured out how to work it.

When releasing the lock to close the blade, you don't have to put your precious fingers in harm's way and the natural inclination is not to do so, making the AXIS Lock safer to use. It is possible to close some lockbacks without placing a finger or two across the slot while releasing the lock and closing the blade, but the most natural action is to do so. With a traditional liner lock, it is virtually impossible not to place the thumb across that

opening to release the lock, the exception being some few knives with alternate operating mechanisms that haven't really caught on for a variety of reasons. I know many who have seriously cut themselves while closing these knives. Not as many as have cut themselves with non-locking knives, but it is a definite risk.

You don't want a folding knife to open except when desired, any more than you want it to close unexpectedly. The design of the AXIS Lock naturally incorporates a detent to keep the lade closed as the locking bar moves over-center of the sculpted blade tang. This also serves to assist in closing the blade the last approximately 25° of travel. On opening, once moved over-center, there is virtually no resistance to rotation until the blade is fully opened and locking in place. For even quicker opening or closing, you can manually pull the AXIS Lock bar back and with a quick flick of the wrist, open or close the blade. This can be a handy trick at times.

The Bane Of Folders

The bane of folding knives is strength compared to a fixed blade. For the significant advantage in convenience that a folder offers for everyday carry, you give up a measure of strength. Strength is a somewhat nebulous term, covering a host of areas, but for purposes of this discussion we are concerned with the blades ability to withstand vertical loads without closing or failing, as well as side loads without failing. The bane of folding knives is strength compared to a fixed blade. For the significant advantage in convenience that a folder offers for everyday carry, you give up a measure of strength. Strength is a somewhat nebulous term, covering a host of areas, but for purposes of this discussion we are concerned with the blades ability to withstand vertical loads without closing or failing, as well as side loads without failing.

Resistance to vertical loads is limited by a number of factors and boils down to the proverbial weak link. At some point any folder will fail, the only question is where. Will it be at the pivot for the blade, or the point at which the blade and the lock interface,

at the blade stop, or will the lock mechanism itself fail first?

In lockbacks, the most common failure is the small pivot pin which secures the locking mechanism, or the tab of the lock or notched tang of the blade. With liner lock designs, the failure modes tend to be more complicated, but it is most often the blade pivot that fails first on better quality knives, but lesser quality knives with thin stainless liner locks often fail when the lock itself is compressed beyond its capabilities and crumples--or slips,

another failure mode for liner locks. Still, it must be said that there are some very strong knives made with both these mechanisms. Often that strength comes with some degree of inconvenience in operation or at considerable expense.

The AXIS Lock addresses the strength question by ensuring that the lock itself will not likely be the weak link. Benchmade says that in testing the lock supported loads in excess of 200 lbs. without damage. That makes sense when you realize that the locking bar is supported in shear at both ends and the sideplates themselves will both have to give way in the metal over the slot in order for the lock to fail completely. Provided there is adequate meat there, that bar isn't going anywhere anytime soon.

Reliability

Lock reliability involves how likely the lock will lock under

various conditions and whether it might inadvertently open. Lockbacks tend to be somewhat less sensitive to dirt and fluid contamination than liner locks, but both are susceptible. In a lockback, a bigger danger is that accumulations of lint and dirt in the recess of the locking tang which can prevent the lock from fully engaging. Liner locks rely upon very tight tolerances and an interference fit. Liquids seem to be their biggest problem, from a contamination standpoint, but dirt can also cause problems, especially over time as things wear and tolerances loosen up. However, the liner lock's most frequent failure mode seems to be failure to engage fully simply due to the user's failure to open the blade with enough force. In many designs, especially inexpensive ones, slow or "soft" opening doesn't allow the lock to engage the tang with full effect and it more easily slips as a result. Lock reliability involves how likely the lock will lock under

various conditions and whether it might inadvertently open. Lockbacks tend to be somewhat less sensitive to dirt and fluid contamination than liner locks, but both are susceptible. In a lockback, a bigger danger is that accumulations of lint and dirt in the recess of the locking tang which can prevent the lock from fully engaging. Liner locks rely upon very tight tolerances and an interference fit. Liquids seem to be their biggest problem, from a contamination standpoint, but dirt can also cause problems, especially over time as things wear and tolerances loosen up. However, the liner lock's most frequent failure mode seems to be failure to engage fully simply due to the user's failure to open the blade with enough force. In many designs, especially inexpensive ones, slow or "soft" opening doesn't allow the lock to engage the tang with full effect and it more easily slips as a result.

The AXIS Lock inherently provides far less opportunity for a less than full engagement. Its design, a ramp with a round bar lock riding up it, is inherently self-engaging and also less susceptible to any wear problems since it is self-correcting. Any wear that might occur will simply result in the lock engaging the tang more fully. It is also pretty much self-cleaning and slow opening doesn't seem to make any difference in how tightly it locks. It can only slip if both springs failed at the same time, an unlikely event. The two "omega" springs are somewhat redundant and even should one fail, there

is adequate tension to engage the lock with just one.

A potential problem with the lockback and liner lock are that many are designed so such that under some circumstances it might be possible to inadvertently disengage the lock while gripping the knife tightly. The sort of "death grip" that might occur under stressful conditions. The AXIS Lock design makes this almost impossible.

Now you know why I love the AXIS Lock. It addresses virtually every shortcoming of other locks and has a few nifty tricks of its own. It may not be perfect, but it's pretty damn close and the best currently available blade lock, in my opinion.

Doug Ritter

|